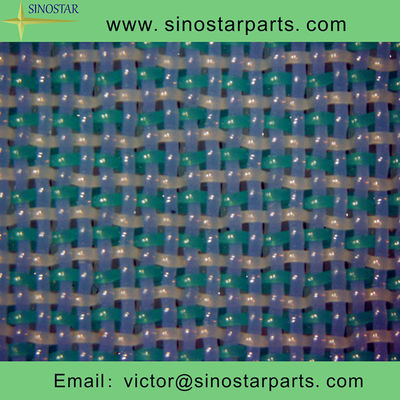

triple layer polyester forming fabric (cxw563520-1)

Model of fabric:563520-1

Top warp diameter:0.15mm Bottom warp diameter:0.20mm

Weft diameter:0.15mm,0.15mm/0.35mm(PET),0.35mm(PA66)

Warp density:70 thread/cm Weft density:55 thread/cm

Breaking strength:≥1000N/cm Jointing strength:≥500N/cm

Air permeability (m3/m2h):313CFM(5000m3/m2h )

Thickness:1.03mm Max. Elongation at 50N/cm:<0.40%

Specifications

Paper machine forming fabrics / screen

Effective management

Strict quality control

Professional design team

3 layer (triple) polyeseter forming fabrics parameter

|

Model of

fabric

|

Wire Diameter

(mm)

|

Density

(thread/cm

|

Air

permeation

m3/m2h

|

Strength

(N.cm)

|

Max.

Elongation

at 50N/cm

|

Thickness

(mm)

|

|

warp |

weft |

warp |

weft |

surface |

jointing |

|

cxw364024-1 |

0.2/0.2 |

0.2/0.2/0.4 |

42-43 |

48-49 |

7200 |

>1000 |

>700 |

<0.7% |

1.35 |

|

cxw364024-2 |

0.2/0.2 |

0.2/0.2/0.4 |

42-43 |

52-53 |

6500 |

>1000 |

>700 |

<0.7% |

1.35 |

|

cxw364524-1 |

0.2/0.2 |

0.2/0.2/0.45 |

42-43 |

42-43 |

7500 |

>1000 |

>700 |

<0.7% |

1.45 |

|

cxw364524-2 |

0.2/0.2 |

0.2/0.2/0.45 |

42-43 |

47-48 |

6500 |

>1000 |

>700 |

<0.7% |

1.45 |

|

cxw561320-1 |

0.15/0.2 |

0.13/.013/0.2 |

66-67 |

66-67 |

6000 |

>1000 |

>600 |

<0.65% |

0.8 |

|

cxw561320-2 |

0.15/0.2 |

0.13/0.13/0.2 |

66-67 |

70-71 |

5500 |

>1000 |

>600 |

<0.65% |

0.8 |

|

cxw561520-1 |

0.15/0.2 |

0.15/0.15/0.25 |

66-67 |

58-59 |

6000 |

>1000 |

>600 |

<0.65% |

0.9 |

|

cxw561520-2 |

0.15/0.2 |

0.15/0.15/0.25 |

66-67 |

60-61 |

5500 |

>1000 |

>600 |

<0.65% |

0.9 |

|

cxw563520-1 |

0.15/0.2 |

0.15/0.15/0.35 |

66-67 |

55-56 |

5000 |

>1000 |

>600 |

<0.65% |

1.02 |

|

cxw563520-2 |

0.15/0.2 |

0.17/0.2/0.35 |

66-67 |

55-56 |

4000 |

>1000 |

>600 |

<0.65% |

1.08 |

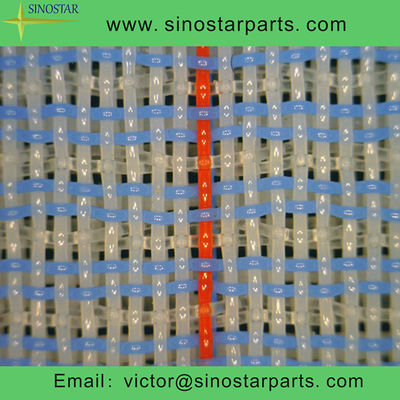

Paper machine forming fabrics are designed to retain as much fiber and other furnish components as possible

while allowing water to drain through them as quickly as possible. These fabrics are typically produced from

monofilament strands or yarns that are woven together in a pattern that can be classified by their fabric style

(or weave);mesh, count, and diameter; surface topography; and air permeability. This module discusses how

each of these characteristics affect final sheet quality.

A sheet of paper begins in the forming section, where a mixture of 99% water and 1% cellulose fiber is

introduced evenly across a forming fabric, which acts as both a sheet conveyor and a dewatering device.

It is here that the paper sheet is formed and the initial water removal occurs. As the fabric moves, water

drains through it, while the fibers and fillers that form the sheet remain on top. Today, forming fabrics have

an average operating life of 45 to 60 days. Multilayer technology offered by Maanshan Sinostar is the

standard today on world-class high-speed machines.

Polyester Forming Fabrics / Screen Features:

1.High quality monofilament material imported form Germany,

2.Polyamide monofilament is added in the weft, On the machine side of Polyester Vacuum Forming Fabric.

3.Acid-resistant, wear-resistant, alkali-resistant,non-toxic, high temperature (in the 180-degree can be a long time operation),while net body smooth,tensile strong,good ventilation,running smoothly,

no seam marks,no static charge,wide adaptability,and longer working life.

Polyester Forming Fabrics / Screen Application:

4-shed single layer polyester forming fabric/ Paper machine clothings is suitable for making culture,

writing printing and packing papers etc.

5-shed single layer polyester forming fabric / Paper machine clothings is suitable for making toilet paper,

printing and packing papers etc.Especailly,in Iran,it is used to make Kraft paper,corrugating paper,etc.

8-shed single layer polyester forming fabric / Paper machine clothings is suitable for making high basic

weight paper and packing papers.such as kraft paper,flutting paper,corrugating paper and others.

1.5 layer polyester forming fabric /Paper machine clothings is used widely to make writing printing paper,

Kraft paper,corrugating paper,etc.

8-shed,16-shed double and a half layer ones is suitable for quality printing paper, tissue paper and surface

pulp, inner pulp and base pulp of the board paper.

Three layer multi-shed forming fabric,SSB wire, is suitable for making quality printing paper.good adptability

on high speed of paper machine.

Our product range:

Maanshan Sinostar Industry Co.,Ltd is a professional industrial and trading company. We are specialized in

all kinds of paper proceessing machinery parts:

1).Paper machine clothings(PMC) including:

Polyester forming fabrics ,dryer screens, spiral dryer fabrics,sludge dewatering mesh,pulp washing mesh,

press felt, polyester screen printing fabrics, stainless steel wire mesh,etc.

2).Pulping equipments including:

High density cleaner,low density cleaner,refiner plates,refiner discs,pressure screen baskets,screen plates,etc.

3).Industrial blades including:

Doctor blade,paper cutting knives,shearing blades,slitting knives,cutting saw blades,round blades,etc.

4).Other paper machinery components including:

Shaft sleeve,Shatter jet,Bronze plain bearing,etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!