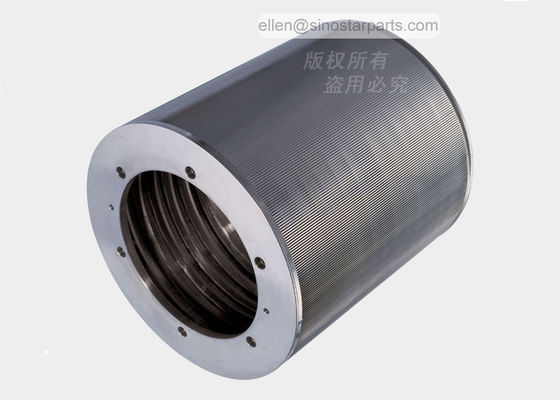

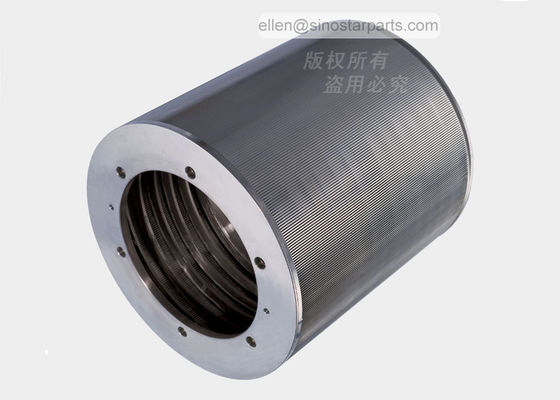

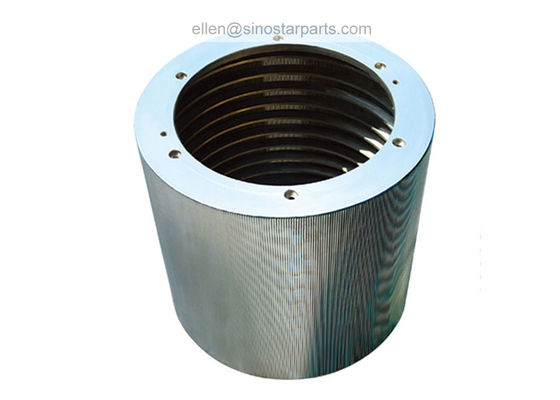

Paper making stainless steel slotted inflow pressure screen basket

Application

it can be used as paper stock screening equipment before paper machine or fine screening in pulp production system.It can be coarse screen or a fine screen for all kinds of stock and different screening process.

Design Feature

Impurities in the outside of the screen cylinder and get rid of the screen rid of the screen cylinder in the centrifugal force generated by rotor’s rotation,separate the impurities from the paper machine to be in proper running with less broken paper. Great throughput with more long fiber,lower power consumption,high screen efficiency with less rejects.the capability may be different according to different pulp variety and concentration,so the capability in the below chart is only used for choosing the model.The in flow pressure screen has good adaptability and high production capacity.High efficiency, lower energy consumption, lower operation cost.

It is suitable to be as fine screen for waste paper.the screen cylinder gains long life and high throughput with the bar structure.it is convenient to clean the screen slot with high pulsing frequency in the structure of multifoil or drum rotor. The multifoil rotor promotes the axial mixture for the stock to avoid stock thickening in the screening process.

- Good adaptability with high production capability.

- High production efficiency with high flow speed.

- High removal of the adhesive materials.

- Lower power consumption.simple structure and easy maintenance.

The capability may be different according to different pulp variety and concentration,so the capability in the below chart is only used for choosing the model.

All of our screening products are based on sound science.Not guesswork or myths or magic wands – but a thorough understanding of physics, fluid dynamics, mechanical forces, slot tolerances, rotor clearances, and the nuances of pulp suspensions.

Major techical data:

Range of basket diameter: < Ø1600mm

Range of screen plate: 2000 x 6000mm

Minimum slot width: 0.10 mm

Min. orifice diameter: Ø0.8 mm

Material: SUS316L, SUS316, SUS304/321

Wearing layer thickness: 0.2 0.5 mm

Basket cylindrical accuracy: 0.5 mm

Electric-chemical polish: no fiber strining

Production capacity:

Wedge wire basket: 2000 sets / annual

Orifice plate: 4000 square meter / annual

Slot plate: 1000 square meter / annual

Other basket: 1000 sets / annual

|

Material

|

Stainless steel

|

Type

|

Wedge wire

|

|

Flow configuration

|

Inward flow basket

|

Screen slot size

|

0.30mm

|

|

Inside diameter

|

755mm

|

Packing size

|

940X940X940mm

|

|

Height

|

830mm

|

Chrome plated

|

250Micron

|

| Inflow Processing Specification |

| Material |

SUS 316L |

| Width of slot |

0.1mm |

| Size |

Min |

Max |

| Inside Diameter |

305mm |

1900mm |

| Height of screen |

267mm |

1650mm |

| Thickness of screen plate |

5mm |

10mm |

Sinostar Screens offers the largest selection of basket design in the industry.

Our pressure screen baskets are custom designed and manufactured to meet customer specifications. Available in wedge wire, electron beam drilled or milled slotted, these baskets add quality to any pressure screen assembly.These baskets can also be designed to fit headbox applications. All of our screening products are based on sound science.Not guesswork or myths or magic wands – but a thorough understanding of physics, fluid dynamics, mechanical forces, slot tolerances, rotor clearances, and the nuances of pulp suspensions.

We continually evaluate and invest in new manufacturing technologies to ensure:

- Superior strength

- Excellent roundness

- Precise slot tolerance

- Outstanding surface finish

Our cylinders are delivered with minimal lead times and consistent quality to lower the total cost of screening for our customers.we use our knowledge and experience to select the wire that best fits your process parameters,production levels,and quality requirements.

Product range

Sinostar Industry Co.,Ltd is an industrial and trading company.

We are specialized in paper processing machinery parts for many years,our main products:

1.paper making clothing,including: polyester forming fabrics,spiral dryer fabrics,sludge dewatering belt,screen printing mesh,stainless steel wire mesh,etc.

2.Paper and pulp cleaner,including: high density cleaner, low density cleaner.

3.Other Paper-making parts,including: doctor blades,spray nozzles,pressure screen baskets,refinerr plates,etc.

Whereever you are,Sinostar products can be sent to you any part of the world quickly and cusotmer can assured in using it.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!